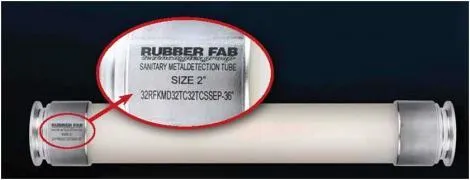

Metal Detection Tubing

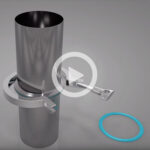

Used as a component to metal detection equipment, this Metal Detection Tube can help send a signal to reject contaminated products

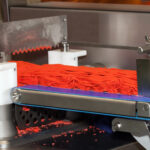

Rubber Fab’s Metal Detection Tubes are used as a metal detection machine component for viscous products such as liquids, slurries, syrups, pastes and many other pumped products. When metal is detected in the product flow, a reject signal is channeled to one of the available output relays. The output relay can be used to activate a ball valve, control a visual or audio alarm or send a signal to a PLC and release the rejected product, therefore minimizing product loss and costly downtime.

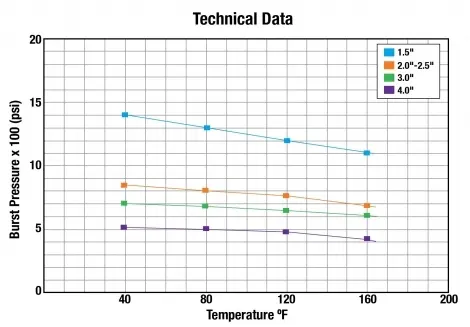

Rubber Fab’s sanitary metal detection tube assemblies are manufactured using steam-cleanable USDA, FDA approved schedule 80 PVDF pipe suitable for system temperatures of -40°F to +240°F, and 316L sanitary Tri-Clamp® connections.

Available sizes: 1.5″ – 4″

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

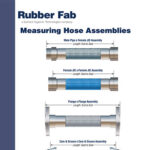

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Alcohol Processing

Alcohol Processing Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive