O-Rings

O-rings work in different applications than Tri-clamp® gaskets

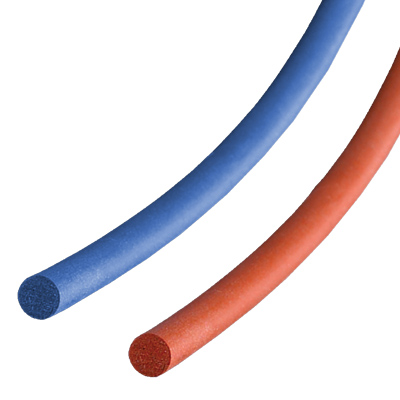

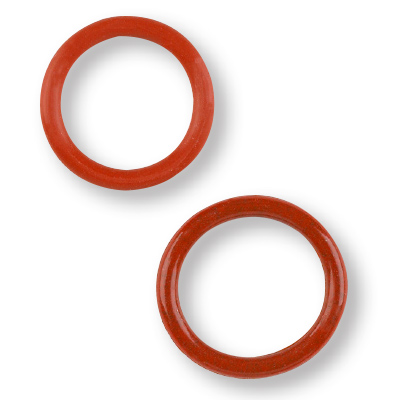

Seal design is an important factor in food, dairy, beverage and pharmaceutical processing. An o-ring is a very important part of that design. O-rings are generally installed in a seal to prevent leaking, or loss of fluid. Rubber Fab offers AS568 Standard o-rings, metric, DIN and custom sizes in a wide variety of materials.

There are many factors to consider when choosing an elastomer for your application. O-rings and gaskets are FDA Compliant for use in food applications and Class VI tested for pharmaceutical applications. Rubber Fab Detectomer® products meet and exceed the standards set by the Food Safety Modernization Act. They are detectable by in-line x-ray inspection and metal detection systems, as well as, magnetic separators, therefore reducing costly product loss and recalls.

Quad rings are a unique o-ring with a unique profile, doubling the sealing surface of a traditional o-ring. This design also provides lower friction and because it has more of a square profile, and can resist spiral twisting.

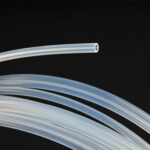

Chemical attack and swelling are the primary causes of o-ring failure. Encapsulated o-rings match the chemical and temperature resistance of solid PTFE o-rings, and possess properties of elasticity and recovery, which are crucial in many sealing applications. Encapsulated o-rings are virtually chemically inert and provide easy cleanup of viscous materials.

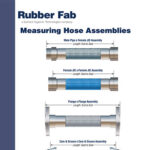

Want to see the measurements of all the sizes we offer? Click the link to head to our downloaded PDF brochure.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Sanitary End Caps

Sanitary End Caps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Data Center Cooling

Data Center Cooling Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

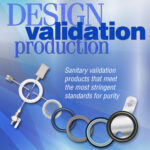

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive