O-Ring Applications

O-ring applications are important and are the deciding factor in picking an o-ring

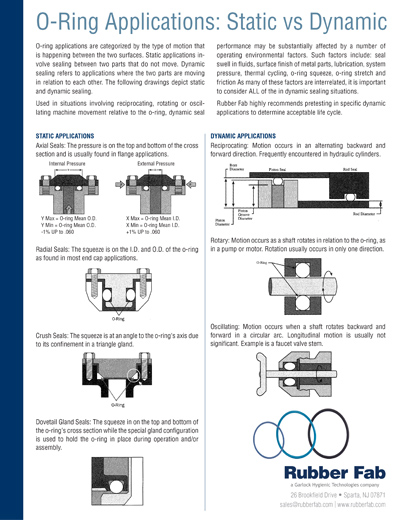

O-ring applications are categorized by the type of motion that is happening between the two surfaces. Static applications involve sealing between two parts that do not move. Dynamic sealing refers to applications where the two parts are moving in relation to each other. The following drawings depict static and dynamic sealing. Used in situations involving reciprocating, rotating or oscillating machine movement relative to the o-ring, dynamic seal performance may be substantially affected by a number of operating environmental factors. Such factors include: seal swell in fluids, surface finish of metal parts, lubrication, system pressure, thermal cycling, o-ring squeeze, o-ring stretch and friction As many of these factors are interrelated, it is important to consider ALL of the in dynamic sealing situations. Rubber Fab highly recommends pretesting in specific dynamic applications to determine acceptable life cycle.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

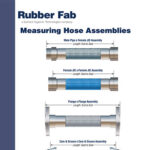

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Sanitary End Caps

Sanitary End Caps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Data Center Cooling

Data Center Cooling Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive