The RFPOC PTFE Lined Hose in Cosmetic Manufacturing

For the best possible product, this cosmetic manufacturing plant turned to the RFPOC Hose

INDUSTRY: Cosmetics – Facial Skin Care

CUSTOMER: A well-known consumer brand offering Beauty, Nutritional, and Cosmetic products in North America and around the World. They offer a wide portfolio, with most products manufactured in-house using flexible production processes ranging from short-run pilot programs all the way up to full-scale large batch campaigns.

BACKGROUND: The customer was using Clear Non-Reinforced PVC hoses in the transfer of liquid (a hot-mask cosmetic product) via AODD Diaphragm Pump through their manufacturing process. Even though the hoses had been specified during plant construction, new products and processes introduced over the years were creating application conditions outside the original specification. These conditions created unexpected and premature failure of the PVC hoses, resulting in leakage and loss of product.

CHALLENGES FACED: The high viscosity of the cosmetic fluid/paste meant that elevated temperatures and pressures were required, above those normally demanded from the processing lines and equipment. While the stainless steel vessels and pipework provided sufficient compatibility for the more extreme conditions, flexible hoses were still required for transfer of media between process vessels and bottling lines and thus presented a potential weak spot in the process. Therefore, the customer recognised that a new solution was required to minimise un-scheduled downtime and reduce their costs for maintenance and clean-up.

OPERATING CONDITIONS:

- Size – 1.5″ and 2″ ID and 36″ through 120″ lengths

- Temperature – 200°F (93°C)

- Application – Hose Transfer with Tri-Clamp Connections

- Media – Aqueous Cosmetic Fluid/Paste

- Pressure – 75 PSI (5.2 bar)

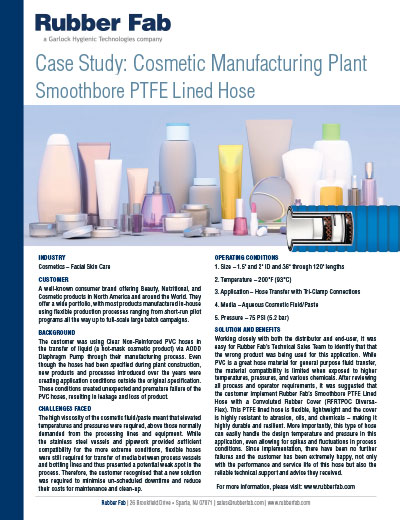

SOLUTION AND BENEFITS: Working closely with both the distributor and end-user, it was easy for Rubber Fab’s Technical Sales Team to identify that that the wrong product was being used for this application. While PVC is a great hose material for general purpose fluid transfer, the material compatibility is limited when exposed to higher temperatures, pressures, and various chemicals. After reviewing all process and operator requirements, it was suggested that the customer implement Rubber Fab’s Smoothbore PTFE Lined Hose with a Convoluted Rubber Cover (RFRTPOC DiversaFlex). This PTFE lined hose is flexible, lightweight and the cover is highly resistant to abrasion, oils, and chemicals – making it highly durable and resilient. More importantly, this type of hose can easily handle the design temperature and pressure in this application, even allowing for spikes and fluctuations in process conditions. Since implementation, there have been no further failures and the customer has been extremely happy, not only with the performance and service life of this hose but also the reliable technical support and advice they received.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Sanitary End Caps

Sanitary End Caps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Data Center Cooling

Data Center Cooling Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive