Keeping Data Centers Cool: Full Range of Particulate Elimination

In this case study, a data center maintained the purity of their cooling liquids and ensured it remained free of debris and buildup

INDUSTRY

Data Infrastructure

CUSTOMER

Large Data Center and Networking Solution Providers

BACKGROUND

A Data Center is a building, a dedicated space within a building, or a group of buildings used to house computer systems and associated components, such as telecommunications and storage systems. Data centers are an integral part of processing innovations. The modern age needs functional data centers to process and transfer large amounts of data, a process that generates a lot of heat. For these facilities to work efficiently, they need data center cooling systems in place. Crucial for business continuity, so it generally includes redundant or backup components and infrastructure for power supply, data communication connections, and environmental controls. High demand for electricity from data centers has increased strain on local grids and has increased electricity prices in some markets, thus driving the need for more efficient power usage. With increasing dependency on computing and AI resources, data centers are a fundamental part of our world, and will play an increasing role as our communities & societies rely more on IT data and functionality.

CHALLENGE FACED

As data center density increases, overheating and performance degradation are growing concerns. Liquid cooling has emerged as a more efficient and effective heat management solution in these environments where traditional air cooling is often insufficient. Liquids offer superior heat transfer, leading to improved data center performance. Maintaining the purity of these cooling liquids, ensuring they remain free of debris and buildup, is crucial for maximizing heat dissipation.

OPERATING CONDITIONS

1. Recommended Temperature Range: 18°C (64°F) to 27°C (80°F)

2. Recommended Humidity Range: -9°C (16°F) DP (Dew Point) to 15°C (60°F) DP (Dew Point) and 60% RH (Relative Humidity)

3. Application: Hose Assembly filtration for cooling liquid transfer

4. Media: liquid cooling, common coolants include water, deionized water, glycol/water solutions, and dielectric fluids like fluorocarbons and mineral oils

5. Pressure: Various

6. Size: Various

SOLUTION AND BENEFITS

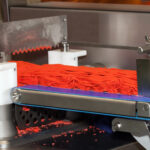

Rubber Fab’s Full Range of Particulate Elimination. The complete elimination of particulates is critical to ensure maximum cooling and flow rates in the data center market. Consider the full range of Rubber Fab’s Fluid Filtration technology. Our fluid filtration gaskets and socks provide the most comprehensive range of stainless-steel mesh and filter cloth, providing a comprehensive elimination of particulate in the flow path, protecting equipment that is in the fluid flow path.

Specifically, the extended sock-shaped mesh gasket offers up to 5 times more open area for 5 times more soil collection capability than conventional screens. They provide greater flow for situations where it is imperative that particulate is removed to ensure maximum cooling capabilities and flow. Due to the large capacity and open screen area, sock screens require less service therefore reducing downtime and costly change-outs, a major consideration with in-line data cooling processes. While protecting expensive processing equipment from foreign matter, sock screens are especially effective in decreasing pump wear and burnout while increasing energy conservation. Regularly used in the transfer of cooling liquids, sanitary sock screens are specifically designed for high volume applications with low pressure drop.

To learn more about the products we offer for Data Center Cooling, click here.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Sanitary End Caps

Sanitary End Caps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Data Center Cooling

Data Center Cooling Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive