Detectomer® Products in Dairy Processing

Detectomer® Products to the Rescue

INDUSTRY: Dairy Processing

CUSTOMER: Grocery chain that processes their own dairy products.

BACKGROUND

Milk is a valuable nutritious food that has a short shelf-life and requires careful handling. Milk is highly perishable because it is an excellent medium for the growth of microorganisms – particularly bacterial pathogens – that can cause spoilage and diseases in consumers. Milk processing allows the preservation of milk for days, weeks or months and helps to reduce food-borne illness.

The strict requirements within milk processing does not specifically account for gasket failures that go undetected. A customer had recently quarantined 250,000 lbs. of product contaminated with rubber particles. They were at the cross roads of manually inspecting the entire batch or possibly disposing of the entire batch because of the contamination. Either decision is costly, not to mention cleaning of the entire production line to ensure that future batches were not contaminated.

CHALLENGES FACED

Although rubber was the culprit for contamination, the customer’s gasket material of preference was PTFE, light blue in color, that did not have significant contrast with the white dairy product where vision systems would have issues detecting. Unfortunately there is not a one-size fits all solution. Customer asked for a better mouse trap to allow them to better detect when there is a seal failure prior to reaching the end of production. Many of the solutions were very costly until the customer compared the solution cost to the cost of labor to inspect the contaminated product and realized that this process would far exceed any available solution in the market.

OPERATING CONDITIONS

- Temperature – 145°F to 180°F

- Application – Tri-Clover connections

- Media – Milk, Frozen Desserts, Eggnog

- Pressure – ≤100psi

- Size – Various

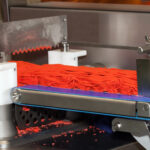

SOLUTION AND BENEFITS

The Detectomer® Family of products were the simple solution due to the inherent properties of the filler material’s ability to be detected with x-ray and/or metal detection technology. These gaskets are fully compatible with all process ingredients and cleaning agents; are physically robust and resilient to abrasive media; provide strong signals in both metal detection and X-ray inspection systems; and remain fully compliant to all industry regulations and standards. In summary, the Detectomer® Family of products ensures long term operational integrity.

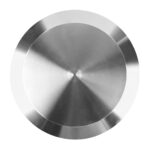

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

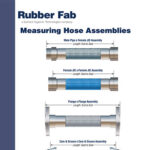

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Sanitary End Caps

Sanitary End Caps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Data Center Cooling

Data Center Cooling Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive