Tuf-Steel® Sanitary Gaskets in Juice Processing

Making the decision to replace gaskets with Tuf-Steel® was more than just a cost effective measure

INDUSTRY: Beverage Manufacturing – Aloe Vera Juice

CUSTOMER: A large US beverage manufacturer, producing natural juices at their production plant in Texas.

BACKGROUND: This customer was using standard PTFE tri-clamp gaskets on their hygienic pipe connections, but was facing ongoing problems with gasket failure. In order to avoid severe leaks throughout their process, they were replacing gaskets on a weekly basis which was not only expensive but also time-consuming for the maintenance crews.

CHALLENGES FACED: Production of aloe vera juice is challenging, and requires careful process control – not only to preserve the biological integrity of the active ingredient, but also to maintain the delicate flavour of the finished product. Mechanical extraction processes (crushing, grinding or pressing of the leaf) create debris, which can damage soft process components and requires frequent cleaning and sterilization cycles between each batch. Additionally, various stages of filtration and stabilization introduce rapid temperature fluctuations from nearboiling point down to flash-cooling, which create physical stresses on hygienic connections as they expand and contract.

OPERATING CONDITIONS:

- Size: 1” to 4” Tri-Clamp (ASME-BPE)

- Temperature: -5°C (23°F) to 95°C (203°F)

- Application: All hygienic process pipe/vessel connections

- Media : Raw extract and purified aloe vera juice

- Pressure: 120 PSI (8.3 bar)

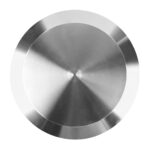

SOLUTION AND BENEFITS: The customer provided full access to the plant and their processing conditions so that Rubber Fab could carry out detailed troubleshooting and recommend the best possible improvements. Taking into account the need for mechanical strength, chemical compatibility, and resilience in temperature cycling conditions, it was recommended that the standard PTFE gaskets were replaced with Tuf-Steel® sanitary gaskets which would not exhibit the creep and cold-flow (and hence leakages) normally associated with PTFE. The unique blend of virgin PTFE and passivated 316L stainless steel provides possibly the most robust gasket material for hygienic applications, which would have no problem to provide a long-lasting and effective seal in these process conditions. Additionally, Rubber Fab’s experience in other sensitive food & beverage applications re-assured the customer that these gaskets would not impart any flavor into the juice. Following a successful trial in one part of the process, Tuf-Steel® was quickly adopted across the whole plant and eliminated all of the leaks that previously caused so many problems. Instead of urgently replacing gaskets on a weekly basis, the customer is now replacing Tuf-Steel® gaskets every 2-3 months as part of scheduled maintenance.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Sanitary End Caps

Sanitary End Caps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Data Center Cooling

Data Center Cooling Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive